Key points

- Engineering controls for noise reduction should be implemented before relying solely on hearing protectors.

- Noise controls are usually simple and can be easy to implement.

What are noise controls?

Noise controls involve modifying equipment or making physical changes to the surrounding environment that reduce the noise level at the worker's ear. Noise controls are not always complicated or expensive, and frequently they may be the most cost-effective option. The cost of implementing noise controls can be offset by savings on the costs of a hearing loss prevention program, workers' compensation premiums, and claims for hearing loss.

Before you implement noise controls, make sure machinery is in good repair and all maintenance procedures have been conducted. Sometimes proper maintenance is all that is necessary to reduce noise to a safe level.

If further sound reduction is needed, some of the following simple noise controls may work. If a more sophisticated solution is necessary, an experienced noise professional should be able to help.

Did you know?

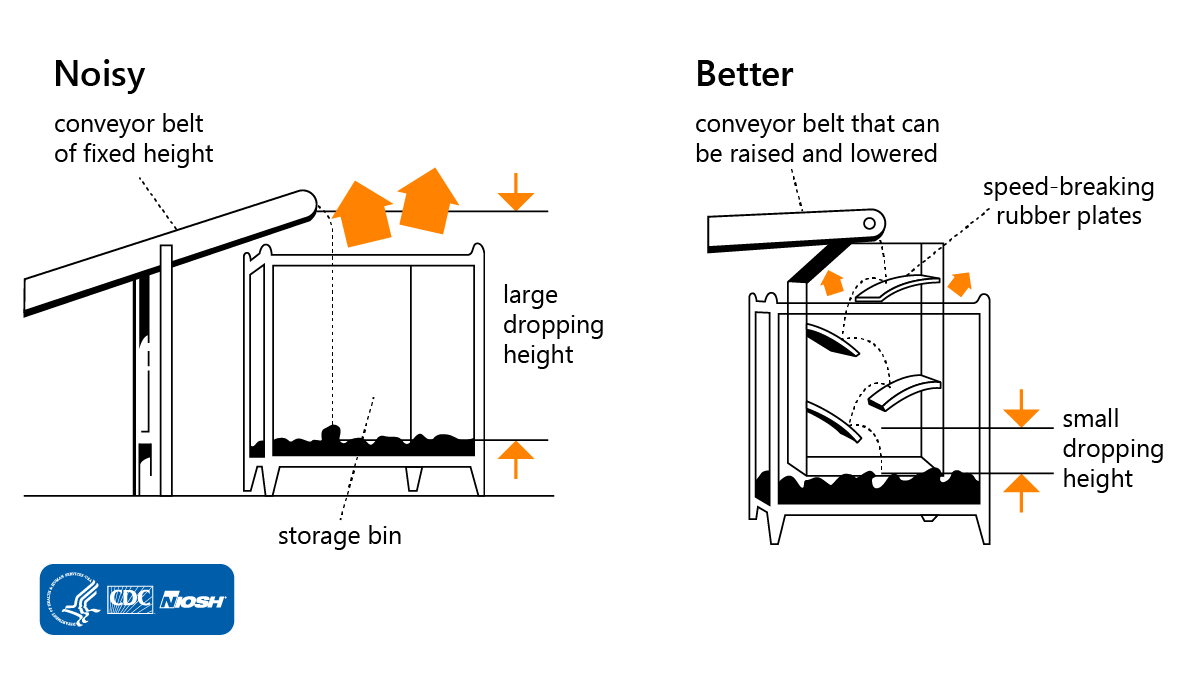

Reduce speed of moving parts

Parts or machinery that are in motion produce less sound energy at slower speeds. For example, slower fans with larger blades are quieter than smaller, faster fans that move the same volume of air.

The same principle applies to noise created by falling parts. The farther they fall, the more speed they pick up on the way. Decrease impact noise of falling parts by decreasing falling distance. For example, use additional rubber plates instead of a single conveyor belt dropping from a height, as shown in the diagram below.

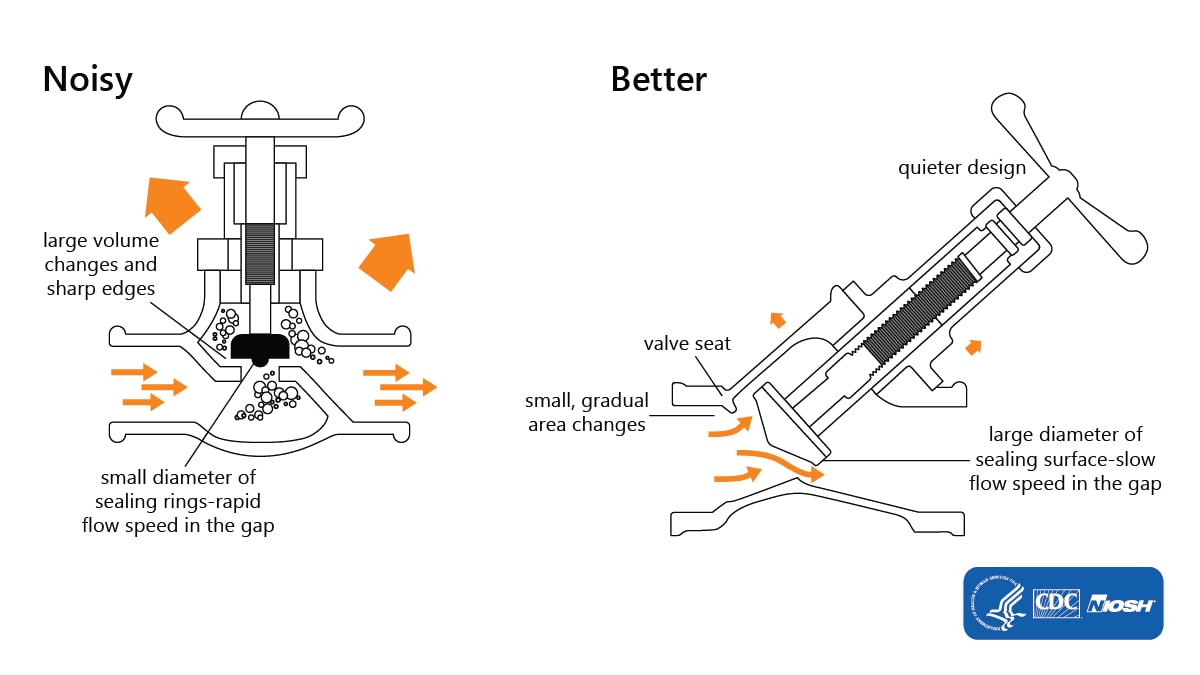

Eliminate restricted flow in pipes or ducts

Restricted flow in ducts and pipes can create extra turbulence which will increase noise. Eliminating obstructions such as flanges and valves can reduce this noise, as shown in the diagram.

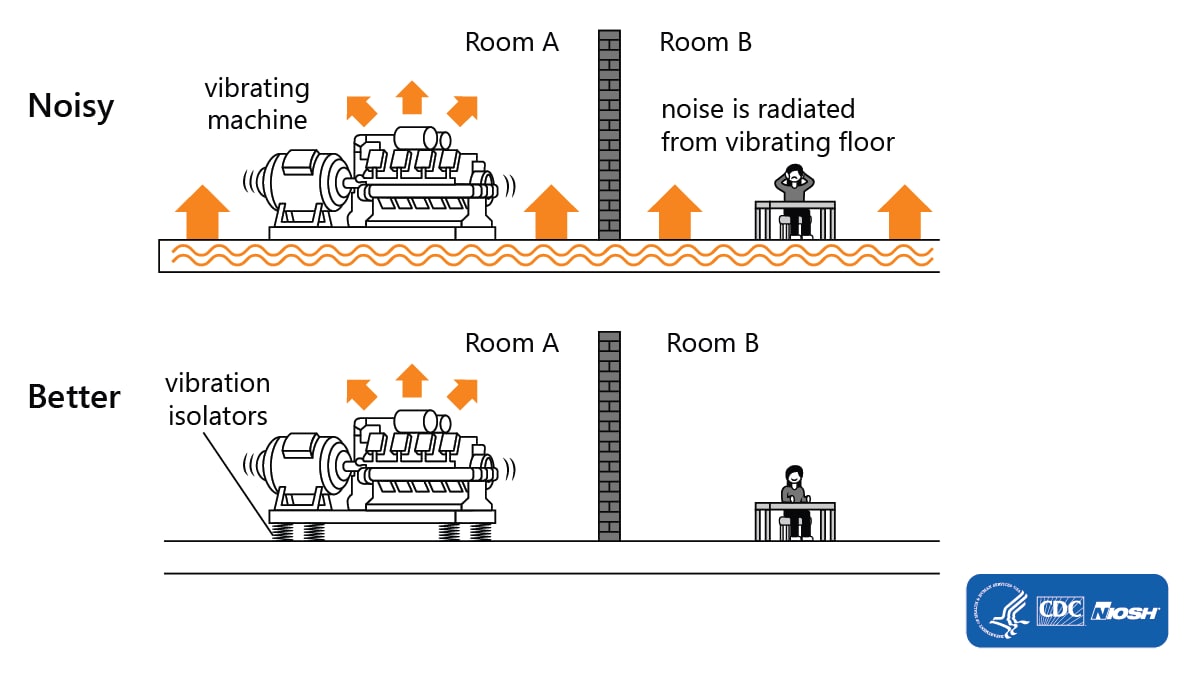

Isolate machine vibration

Vibration isolation of machines can reduce excessive noise. In the first diagram below, the vibrating machine causes noise in the adjacent room. In the second image, the machine has been placed on vibration isolators. This prevents vibrations from travelling through the floor and generating noise where the worker is located. Note that either the machine or the worker’s area can be isolated.

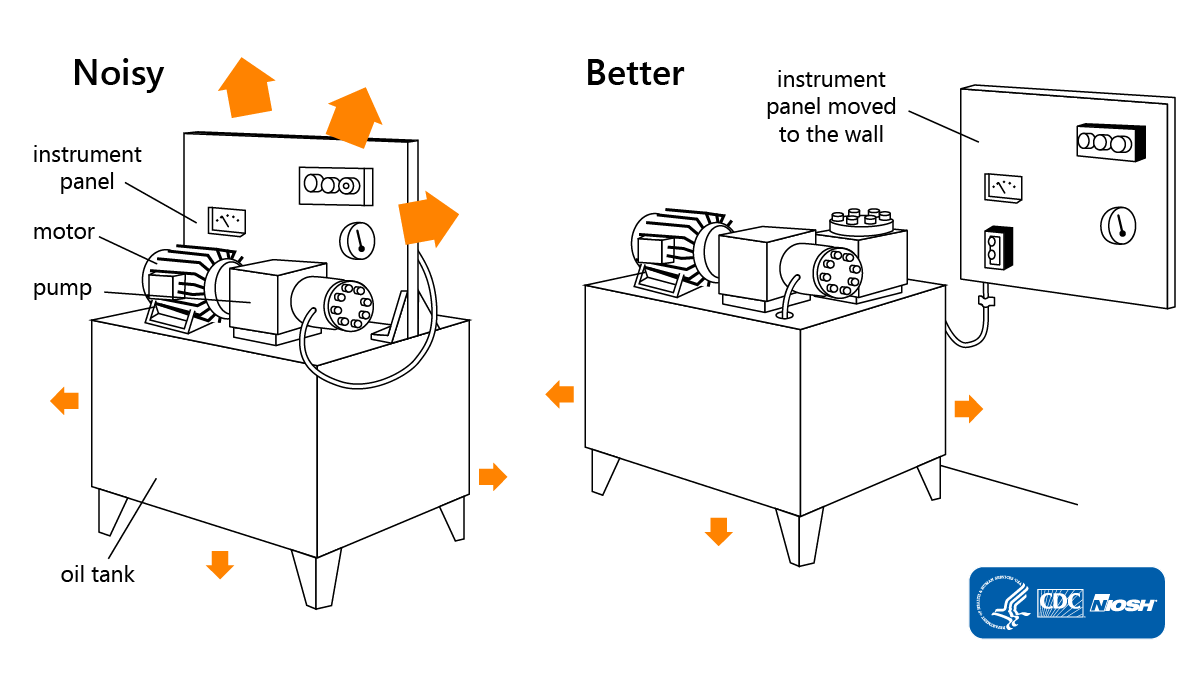

Reduce vibrating parts and surfaces

Panels connected rigidly to vibrating machinery can radiate more sound than the machine alone. Moving instrument or control panels off the vibrating machinery can reduce the total noise from the machine. Securing loose parts can also reduce the noise level.

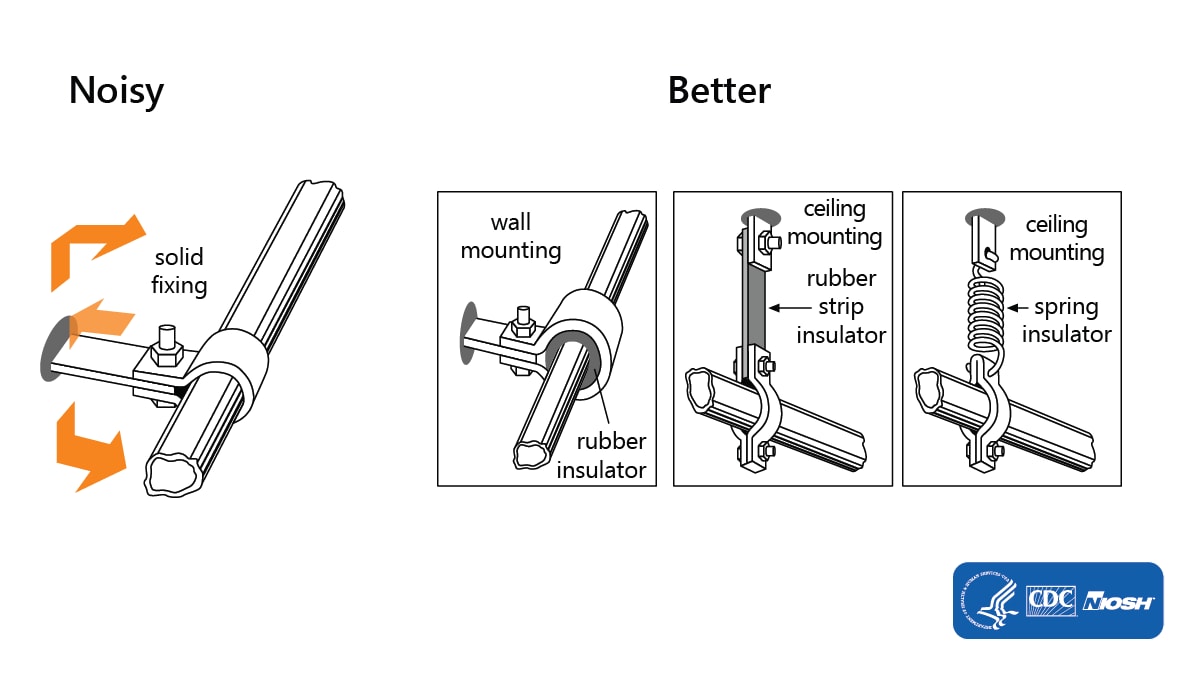

Use anti-vibration connectors

Rigid connections can transfer vibrations to surfaces, such as walls and ceilings. Isolating these noise sources will decrease radiated sound. See the image below for several techniques on how to isolate noise.

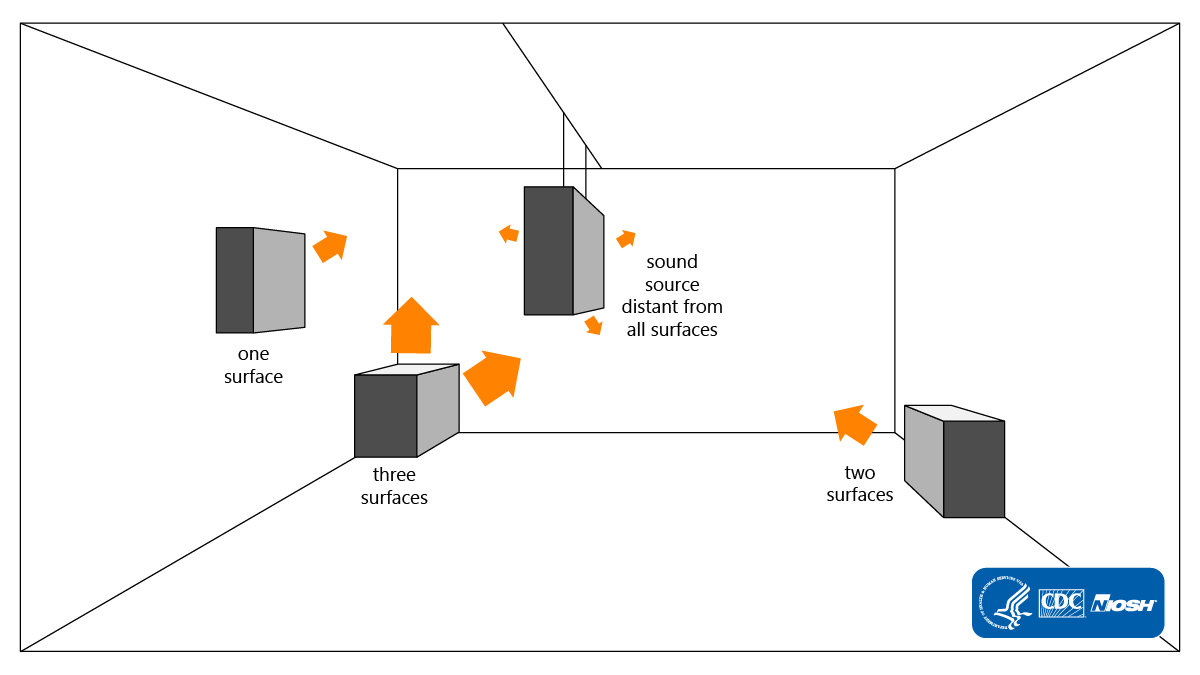

Keep noisy machinery away from walls

Sound reflects from hard surfaces such as walls, floors, and ceilings. These reflections increase the overall noise levels in a space. The closer you place the noise source to a hard surface, the louder the reflected noise will be.

Usually, the best placement for a noise source is away from the walls and suspended between the floor and ceiling. The image below shows a good example of this. The worst placement is in corners, where sound will reflect from three surfaces.

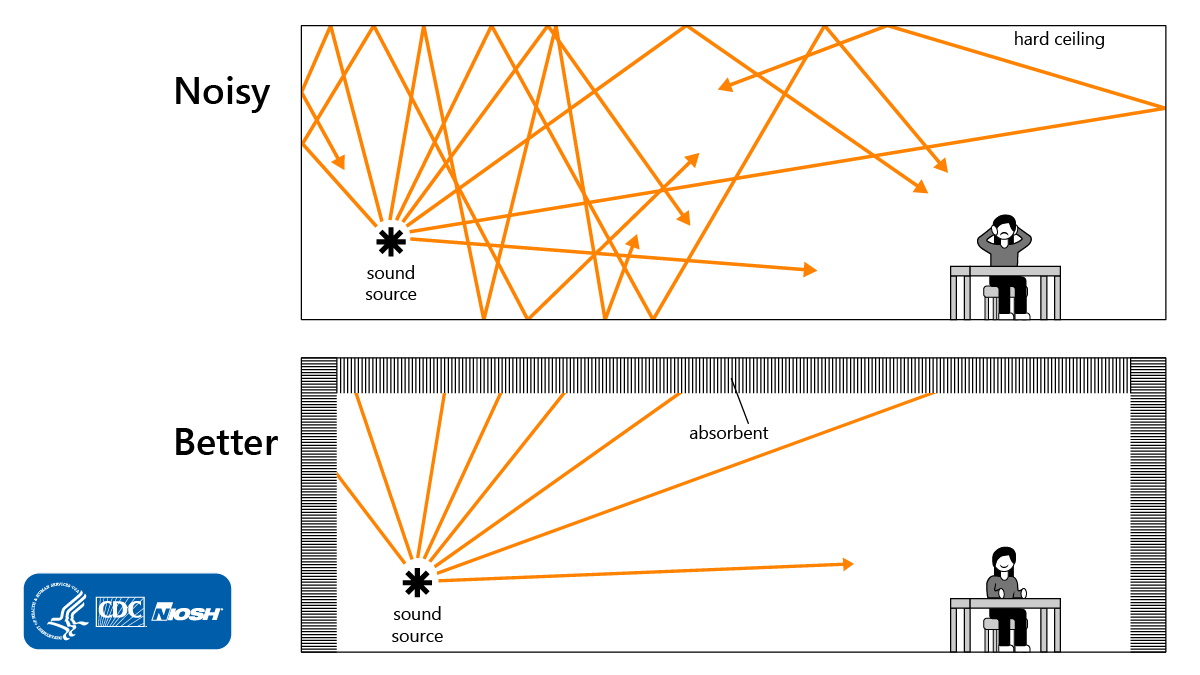

Add sound absorption materials

Sound reflects easily off hard surfaces such as walls, ceilings, and floors. This increases noise levels in a space. Porous materials – such as textiles and foam – absorb sound. Covering hard surfaces with absorptive materials reduces reflected sound and lowers noise levels.

The following are some best practices for using sound absorbing materials:

- Use line enclosures, barriers, and screens with sound absorbers on the noisy side.

- Use thin materials to absorb high frequency noise. Use thicker, absorptive materials to absorb lower frequency noise.

- Hang sound absorbent baffles so that both sides are exposed to the noise. This maximizes surface area for absorption.

- Use hard perforated materials – such as stainless steel microperforated plates – in places where barriers and enclosures need to be cleaned with high temperature or pressure. This can include areas like cleanrooms and food production facilities.

- Consult vendors of sound absorbing materials to help analyze noise levels and recommend commercially available products.

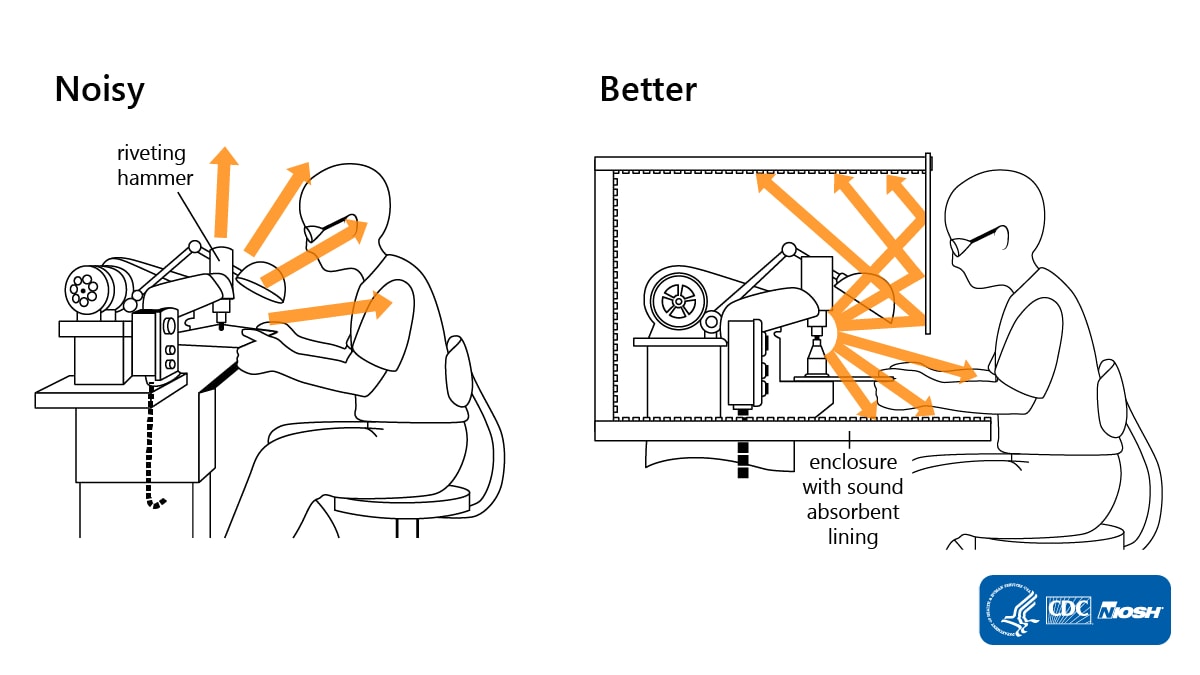

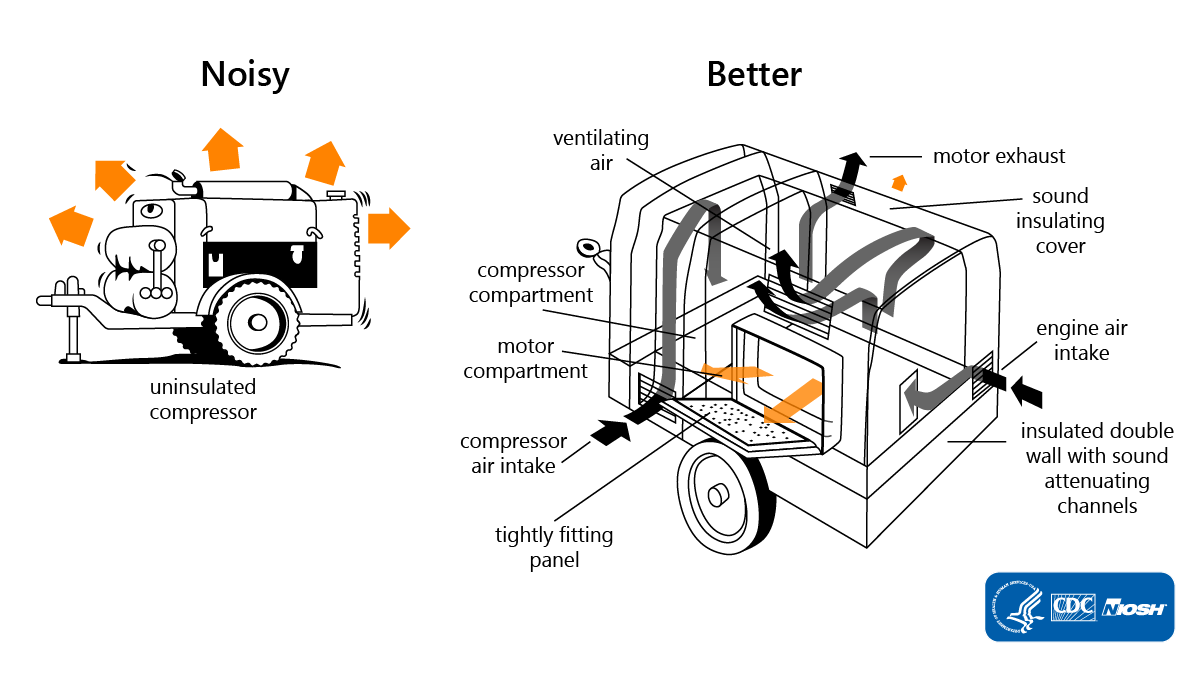

Build enclosures around equipment

Enclosures can block the transmission of mid- and high-frequency sounds. Workplace tasks which can generate mid-high frequency noise include:

- Riveting

- Grinding operations

- Machine cutting

- Compressed air cleaning

Barriers reflect sound away from the worker, as shown in the image below:

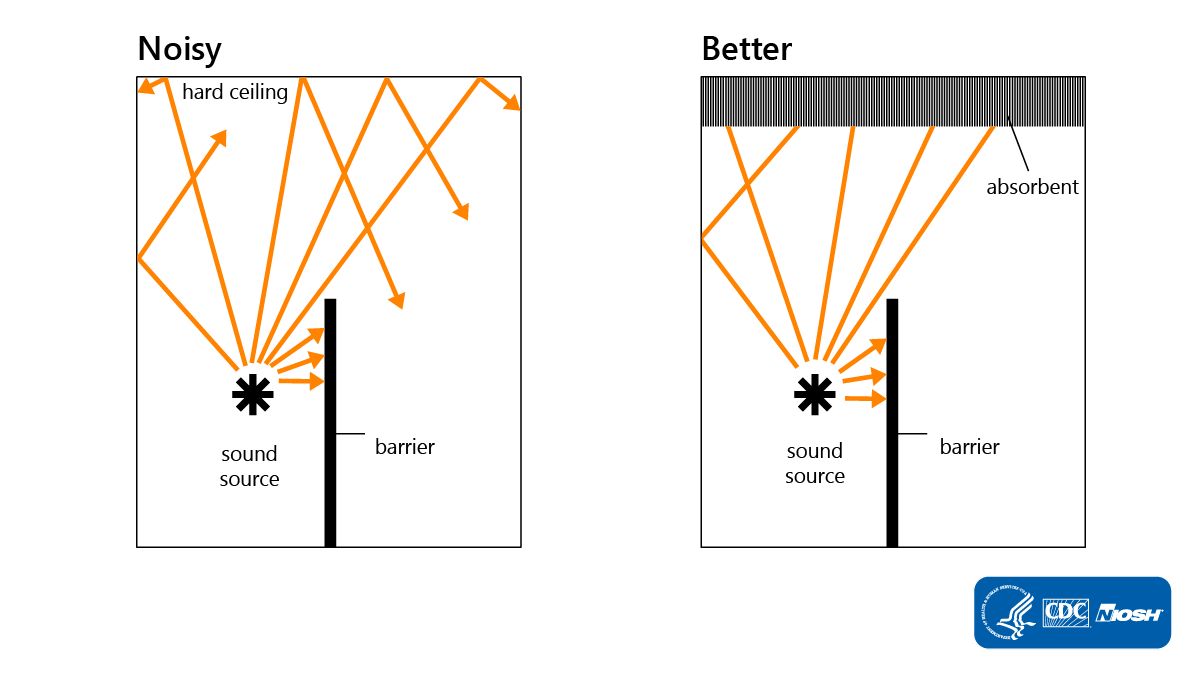

Install barriers

Block high frequency noise by using a barrier (also called a sound shield). A barrier is more effective the taller it is and the closer it is placed to the source. Indoor barriers are more effective if the ceiling is sound absorbent. Barriers are better for high frequency noise and can be less effective for low frequency noise.

Tips for using barriers between noise source and workers

1. Construct barriers from dense material, such as brick or sheet steel. Chipboard and plasterboard can also be used.

2. Always place the barrier either as close to the noise source or the employee position as possible. Barriers in these locations block more sound than barriers placed half-way in between.

3. Add absorbent materials to ceilings to make indoor barriers more effective.

4. Cover the barrier with sound-absorbing material on the side facing the noise source. This will eliminate reflections and reduce the overall sound level.

Seal enclosures for low frequency sources

Low frequency noise travels around corners and through holes and continues to spread in all directions. For this reason, barriers are insufficient to effectively block low frequency noise. A complete enclosure made of a solid material lined with sound absorbent material will help contain low frequency noise. All doors and openings should close tightly.

Tips for enclosure design

1. Build enclosures with dense material and line them with absorptive material.

2. Make operator access opening(s) as small as possible while still being usable.

3. Use partial enclosures for blocking low frequency sound, which requires a fully sealed enclosure.