Purpose

Safety personnel and instructors can use this resource as a training aid to increase awareness about limited-visibility areas around construction vehicles and equipment.

Method

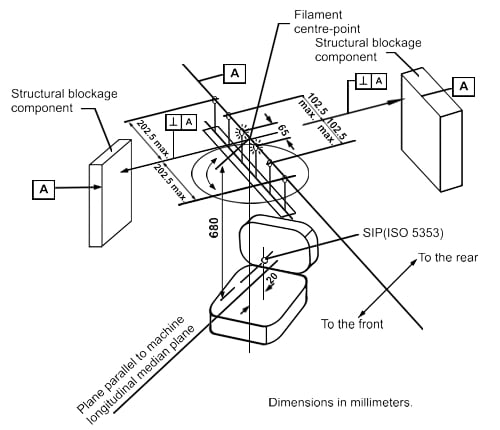

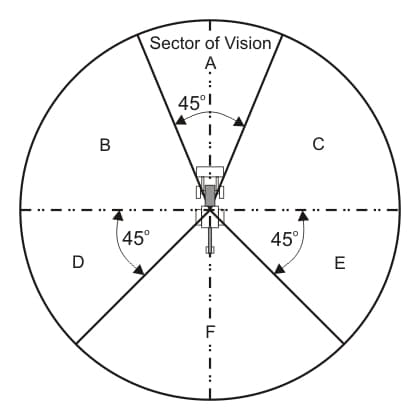

A combination of physical measurements and computer simulation were used to generate the blind area diagrams. Both methods utilized ISO 5006 "Earth-Moving Machinery – Operator's Field of View Part 1: Test Method" test procedure, which uses light sources to represent the operator's eyes. The eye point was representative of the 50th percentile worldwide operator as defined in ISO 3411 "Earth-Moving Machinery – Human Physical Dimensions of Operators and Minimum Operator Space Envelope" and was 680 mm above and 20 mm in front of the Seat Index Point (SIP) as defined in ISO 5353 "Earth-Moving Machinery, and Tractors and Machinery for Agriculture and Forestry – Seat Index Point" (see Figure 1). Light source horizontal spacings as defined in ISO 5006 for the various sectors of vision around the machine, shown in Figure 2, were used for mapping the shadows, which represent the visibility blind areas. These spacings represent the ability of an operator to move his head laterally to see around visibility blockages.

Blind areas were determined for three planes of elevation; the ground plane, a plane at 900 mm above ground to correspond to the height of channelizing devices, and a plane at 1500 mm above ground to correspond to the height of a 4' 11" person. The 1500 mm above ground plane also corresponds to a height that is slightly less than the stature of the 5th percentile operator as defined in ISO 3411. Polar plots of the recorded data were generated with 5-degree increments and 1-meter intervals up to the 12-meter or 24-meter test circle perimeter, depending on machine size.

The indirect visibility, through the use of mirrors, was measured using a single light source in accordance with ISO/CD 14401-1 "Earth-Moving Machines – Surveillance and Rear-View Mirrors, Field of Vision – Part 1 – Test Method."

Physical measurements

The physical measurements test procedure for developing Blind Area Diagrams was conducted in the semi-anechoic building used for sound testing at Caterpillar's Peoria Proving Ground. This facility provided the dark environment needed for the light/shadow technique that was used following methodology in the ISO 5006 procedure. With this methodology, light bulbs, or more specifically filaments, are used to simulate the operator's eyes. The bulbs are mounted on a bar that allows each bulb to be moved horizontally, from a center position, up to 202.5 mm (405 mm total bulb spacing). The actual light support device used for the physical tests is shown in Figure 1. The filament spacing represents the range of eye movement that an operator will use to look around a blockage. Each filament casts a separate shadow due to a visibility blockage. If the two shadows overlap, a dark shadow is created, called a masking or blind area, where neither filament can "see." If the two shadows do not overlap, there is no blind area because at least one filament can "see" the area of interest.

A Pentax R115N Electronic Total Station surveying instrument was used to collect the data points that define the machine boundary and the blind areas. This instrument does not require a prism reflector for measurements and provides rectangular coordinates of the target. The target was mounted on an adjustable height stand for the planes 900 mm and 1500 mm above the ground plane. See Figure 2.

Physical measurements test procedure

- Initial machine placement: The test engineer places the center of the Seat Index Point (SIP) measuring device directly above the center of the visibility test circle. The best practice is to use a plumb bob to center the filament side-to-side with the front-to-back visually approximate.

- Final machine placement: Once the side-to-side position is accurate, place the filament fixture in the cab at 680 mm above and 20 mm in front of the SIP. Use a plumb bob and straight edge to mark a reference point on the side of the machine. Hold the plumb bob at the reference point and move the machine forward or backward as necessary.

- Position the implement attachments as described in ISO 5006. The position depends on the type and size of the machine being tested.

- Adjust the bulb filament spacing for the sector of vision being recorded according to ISO 5006.

- Position the support bar holding the light bulbs perpendicular to the visibility blockage being measured. A technique called "focusing" is used to ensure that the light bar is perpendicular to the vertical blockage. To "focus," the light bar is moved +/- 45 degrees from the approximate perpendicular position. The light bar is "focused" when the dark shadow, if there is one, is at its minimum width. If there is no dark shadow, the blockage does not create a blind area for the given filament spacing. Horizontal blockages are created by hoods, fenders, the bottom edges of windows, etc. and do not have a single point perpendicular to the blockage. In this case, the light bar is rotated to positions that will reasonably capture the blind area.

- Measure and record the blind areas on the ground plane using the surveying instrument and target.

- Repeat steps 3 – 6 until all blind areas in all of the sectors have been recorded.

- Measure indirect visibility areas of mirrors.

- Set surveying target height to 900 mm.

- Repeat steps 3 – 8.

- Set surveying target height to 1500 mm.

- Repeat steps 3 – 8.

Computer simulation

The computer simulation procedure for developing Blind Area Diagrams was conducted using Pro-Engineer (Pro/E) CAD software. Caterpillar Inc., who conducted this procedure, provided the Pro-Engineer machine files for simulation. The Seat Index Point (SIP) coordinates were included in the Pro/E machine file for easy placement of the light test device. Maya software was used to generate the eye-point light sources, the shadows (visibility blockages), and the intersection of the shadows with the three horizontal planes (ground, 900 mm, 1500 mm). Mirrors simulated in this software were used to determine the indirect visibility areas.

Simulation test procedure

- Initial machine placement: The test engineer places the center of the SIP measuring device directly above the center of the visibility test circle. The best practice is to use the coordinate offsets obtained from the Pro/E model and then locate the machine geometry in the Maya software. The 20 mm forward offset of the filament center point in the location of the machine is maintained in the machine geometry Pro/E file.

- The test engineer positions the implement attachments as described in ISO 5006. The position depends on the type and size of the machine being tested.

- The test engineer positions two light sources at 680 mm above and 20 mm in front of the SIP. This point is used as the center point about which the light sources will pivot. Also, the test engineer adjusts the light source spacing for the sector of vision being recorded according to ISO 5006.

- The test engineer positions the "support bar" between the light sources perpendicular to the visibility blockage being measured. A technique called "focusing" is used to ensure that the light bar is perpendicular to the vertical blockage. The light bar is "focused" when the dark shadow, if there is one, is at its minimum width. If there is no dark shadow, the blockage does not create a masking for the given filament spacing. Horizontal blockages are created by hoods, fenders, the bottom edges of windows, etc. and do not have a single point perpendicular to the blockage. In this case, the light bar is rotated to positions that will reasonably capture the masking.

- Once a blockage has been "focused" and a blind area exists, the test engineer saves the rendered file to disk with a descriptive name of the blockage. The rendered image will be a "pie slice" since the lights in the Maya setup file have been truncated to illuminate only the geometry that is being evaluated at the time.

- The test engineer repeats steps 4 and 5 until all sectors and objects have been rendered.

- The test engineer measures indirect visibility areas of mirrors.

- The test engineer creates a new "ground plane" 900 mm above the true ground plane.

- Repeat steps 4 -7.

- The test engineer creates a new "ground plane" 1500 mm above the true ground plane.

- Repeat steps 4 -7.

- The test engineer uses PhotoShop to assemble the pie-shaped renderings into a composite image for each reference plane.

Disclaimer

The blind area diagrams are reproduced as received from the contractor, Caterpillar Inc., under NIOSH contract number 200-2002-00563. The opinions, findings, and conclusions expressed herein are not necessarily those of the National Institute for Occupational Safety and Health (NIOSH). Furthermore, mention of any company or product does not constitute endorsement by NIOSH.